Nind Dairy Services Staff Training Programme

Nind Dairy Services train apprentices in switchboards, compressors, and effluent system programming

Apprentices at Nind Dairy Services receive great hands-on training that is often a bit different from the traditional electrical or plumbing apprenticeship. Here are some of our apprentices or newly qualified staff receiving training and working on some unique in-house projects to improve their problem-solving skills, fault finding, industry knowledge, and experience.

It’s not just skills that are unique to the dairy industry either – skills in commercial switchboards, programming, and mechanical-electrical can all be directly transferred to other areas of industry which are often specialised and in high demand.

Nind Dairy Services train staff in building switchboards for dairy sheds

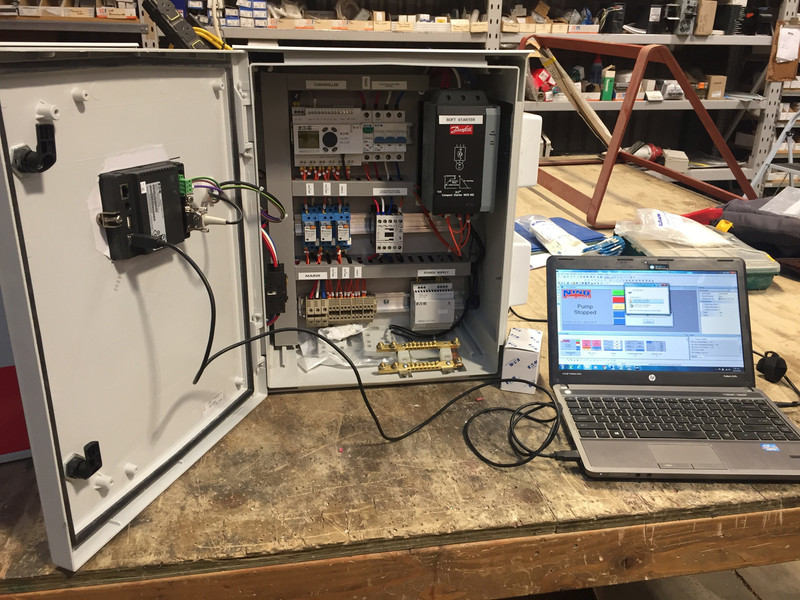

We often have our apprentices make up dairy switchboards in the workshop so that they can gain a greater understanding of how dairy sheds work. They can work independently in a safe environment, with qualified, experienced trainers on hand to answer any questions, check their work over and provide valuable feedback.

They learn about switchboard control wiring, motor overloading, and contactors and have all the resources they need to succeed. Learning their way around the boards in this manner makes it much easier to find faults while out in the field.

Nind Dairy Services train staff in programming touchscreen effluent controllers

Nind Dairy services are unique in that we do all programming for effluent controllers ourselves. This means that we can design our systems, “from the ground up”, how we want them to work. It also means that we can retrofit technology to existing sheds and programme them to meet each customer’s specific needs. Not only does this put us in a better position to meet our customer’s needs, but it provides our apprentices with additional skills and deeper understanding that can really benefit them in the industry.

Nind Dairy Services train staff in repairing and servicing compressors

Nind Dairy Services carry a full range of compressors and offer loan compressors to customers to ensure their dairy sheds keep running during breakdown and maintenance. Compressors are an important part of any dairy shed and are often overlooked until something goes wrong. While Nind Dairy Services do a lot of new dairy fitouts, a lot of our business comes from maintenance servicing which involves developing skills and experience in fault finding and breakdowns. The compressors are a great mix of mechanical and electrical work and our apprentices learn everything they need to know about servicing and repairing them.

Nind Dairy Services value all their staff and are committed to ongoing training and upskilling

We know that the thing that makes Nind Dairy Services stand out from the crowd is our people, so we are always looking for the people with the right attitude who want to learn a wide variety of skills in the electrical or plumbing trade.