Dinnington

Dinnington: Stage Two

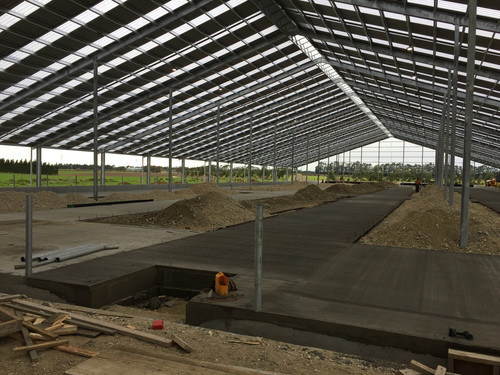

Nind Dairy Services staff have been working hard to get the new Dinnington dairy shed up and running before the start of winter. The wintering barn and milk parlour are well underway. The feed and tractor lane are under construction and concrete has been poured for the cow lane, wintering barn, and robotic milking platform foundation.

Construction of the Wintering Barn at Dinnington is well underway

Wintering barns are gaining popularity in the South Island for a range of reasons, they have been found to have some real advantages, as they help with farm management and can lower nitrogen leaching.

A wintering barn can be beneficial in several ways:

Reducing the pugging of paddocks

Providing better utilisation of supplementary feed

Allowing you better control of grazing management and feeding

Providing shelter for stock during adverse weather (including hot weather)

Better working conditions for staff

Help reduce the cost of wintering cows

Wintering barns do require a change in management and more attention to detail, particularly around nutrition, but can give your farm a wide range of benefits that can help your bottom line.

What’s next in the Dinnington project?

The Lely robots (the Lely Astronaut A4) are set to arrive around the first of May and will take about four weeks to set up and install. The Lely robots take real-time instant analysis of milk and allow you to track the health of every cow. This means things like mastitis, fat and protein content and lactose can all be easily tracked with every individual cow, giving a great insight into each individual cow’s health.

Robot feed out machines will also be installed, so that the cattle can have constant access to feed in the wintering barn, this, in turn, means the cows will eat more, and more input translates to more output, increasing the milk output.

The barn will also use the Lely Discovery 120 Collector robot to clean and collect up effluent. The Lely Discovery 120 Collector robot cleans more efficiently than a scraper, which prevents the cows from standing in manure up to their dew claws, this means a cleaner herd with less likelihood of disease. Check out this video on the cleaner in action:

Dinnington: Stage one

Nind Dairy Services are excited to have started working on Dinnington. Dinnington is a fully robotic shed that will have effluent gobblers, feed out robots and Lely astronauts for automatic milking. The shed will include the latest technology to reduce labour costs and improve automation. There will also be a Grain and Molasses fit out through PPP installed by Nind Dairy Services.

The shed will include the latest technology to reduce labour costs by using automation. Automated milking means cows can literally milk themselves. This allows labour to be freed up on the farm, allowing workers to concentrate on working elsewhere to improve the running of the farm. Feed out robots ensure feed is continually pushed out to cattle increasing the uptake of feed which increases the milk output.

At the moment work is just underway, Nind Dairy Services have put the roof on and are now working on all the underground plumbing and electricity. The Lely robots are set to be sent over from overseas, while we believe the Lely Discovery 120 effluent suckers might actually be the first of their kind in New Zealand.